Here’s a comprehensive explanation of the plate load test:

What it is:

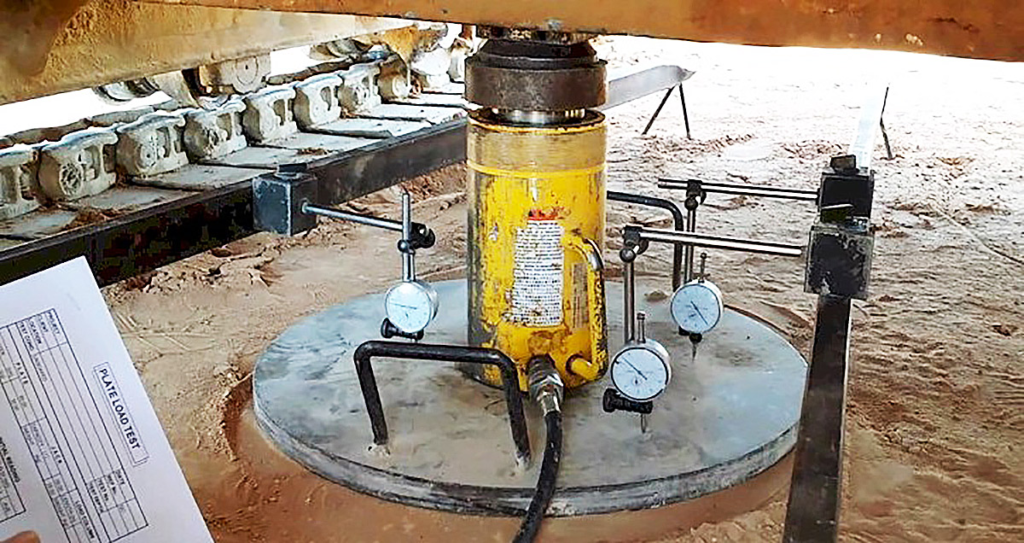

- A field test used in geotechnical engineering to determine the bearing capacity and deformation characteristics of soil.

- Involves applying a gradually increasing load to a rigid steel plate placed on the ground surface and measuring the resulting settlement.

- Provides valuable data for designing shallow foundations, pavements, and other structures that bear on the soil.

Purpose:

- To determine the ultimate bearing capacity of the soil, which is the maximum load it can support before failure.

- To estimate the settlement of a foundation under a given load.

- To assess the suitability of the soil for construction.

- To determine the modulus of subgrade reaction (k), which is a measure of the soil’s stiffness.

- To evaluate the effectiveness of ground improvement techniques.

Procedure:

- Site preparation:

- Level the ground surface.

- Excavate a shallow pit if the test is to be conducted below grade.

- Plate placement:

- Position a rigid steel plate of known diameter (typically 300-750 mm) on the prepared ground.

- Loading frame setup:

- Install a loading frame over the plate, capable of applying a vertical load.

- Instrumentation:

- Attach dial gauges or displacement transducers to the plate to measure settlement.

- Set up a load cell to measure the applied load.

- Load application:

- Apply load in increments, usually doubling every increment.

- Record load and settlement readings at each increment.

- Load holding:

- Maintain each load increment until settlement stabilizes.

- Unloading:

- Gradually reduce the load to zero.

Data analysis:

- Plot a load-settlement curve.

- Determine the ultimate bearing capacity from the curve.

- Calculate the modulus of subgrade reaction (k).

- Analyze the results and draw conclusions about the soil’s bearing capacity and settlement characteristics.

Advantages:

- Relatively simple and quick to perform.

- Provides direct in-situ measurements of soil behavior.

- Can be used to test a wide range of soil types.

Limitations:

- Only tests a small volume of soil, so results may not be representative of the entire site.

- Can be affected by soil disturbance during test preparation.

- Requires experienced personnel to conduct and interpret the test correctly.